2-908-8 Shinmarukohigashi Kawasaki-shi Nakahara-ku Kanagawa-ken 211-0004

JAPAN

Phone: +81-44-433-7171 Fax: +81-44-411-0201

RESIN BOND WHEEL

SHR WHEEL (Super Heat Resisting Bond Wheel)

We are proud to offer you our product, the SHR Wheel, which has greatly improved its retentivity of abrasive grains and has excellent maintainability through a combination of heat resistant resin and special filler.

We are proud to offer you our product, the SHR Wheel, which has greatly improved its retentivity of abrasive grains and has excellent maintainability through a combination of heat resistant resin and special filler.When it comes to using it as a WC cutting tool for an Automatic CNC Tool & Cutter Grinder, SHR Wheel shows high performance at flute grinding and chip breaker processing.

You can depend on Oriental Diamond Tools Lab Ltd's brand new SHR Bond Wheels for your highest demand to:

:improve the life of Resin Bond Wheels you are using for heavy grinding deep cuts.

:improve the life of Resin Bond Wheels you are using for processing of copy grinding and bevel edging.

:improve cost performance using a Resin Bond Wheel from the beginning because it is hard to switch a Metal Bond to a Resin Bond Wheel once set up on the grinder.

:improve cost performance and surface roughness by switching grinding Wheels from metal bond wheels and vitrified bond wheels to resin bond wheels.

RETURN TO PRODUCTS

BRIDEX WHEEL

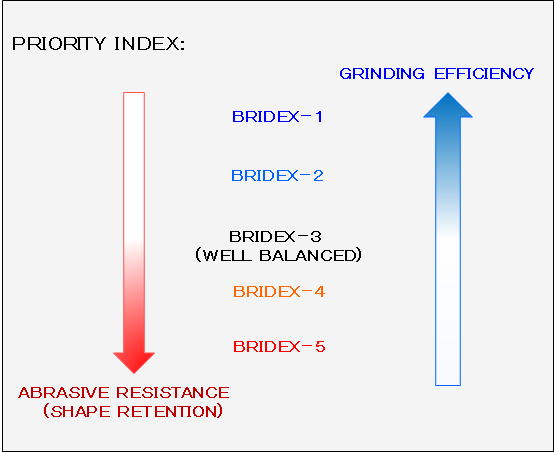

BRIDEX WHEEL is one which is made up of the hybrid bond based on the heat-resistant

special resin we developed from our technology accumulated over many years.

You can get an excellent sharpness and high grinding ratio with this wheel's

characteristic of a strong gripping force of abrasive grains apart from

conventional wheels. You can choose from five types of wheel given priority

to a grinding efficiency (its sharpness) and given priority to the grind

ratio (life). Our BRIDEX WHEELS are used by a large number of customers

at the stage of grinding super hard alloy and processing metal and new

ceramics for electronic devices because customers can realise manufacturing

cost reduction with this wheel's three to five times higher efficiency

compared with the phenolic resin bond wheels.

BRIDEX WHEEL is one which is made up of the hybrid bond based on the heat-resistant

special resin we developed from our technology accumulated over many years.

You can get an excellent sharpness and high grinding ratio with this wheel's

characteristic of a strong gripping force of abrasive grains apart from

conventional wheels. You can choose from five types of wheel given priority

to a grinding efficiency (its sharpness) and given priority to the grind

ratio (life). Our BRIDEX WHEELS are used by a large number of customers

at the stage of grinding super hard alloy and processing metal and new

ceramics for electronic devices because customers can realise manufacturing

cost reduction with this wheel's three to five times higher efficiency

compared with the phenolic resin bond wheels.

RETURN TO PRODUCTS

HIDEX WHEEL

A great number of high rigidity and high precision grinding machines have

been developed as one aspect of recent grinding process innovations and

developments. Even more recently, newer materials such as the difficult

to grind CERMET・ALTIC・MICRO ALLOY have been appearing. Better grinding

machines are also being developed. In these circumstances, the customers'

demands for super abrasive wheels which can process new materials with

high efficiency and ultra-high precision have been on the increase.

Responding to customers' demands, we have developed the HIDEX WHEEL. It uses polyimide resin as the main binding material which shows elasticity and excellent heat resistance. We might also add that compared to the conventional phenol resin wheels, It is an ultra long-life resin bond wheel that boasts of heat resistance and a high grasping power of abrasive grains. Shape retention of the HIDEX WHEEL is approximately three times (index 299) as long as our conventional resin bond wheel(index 100). We're offering four types of HIDEX WHEEL to match the cutting materials and condition of use.

Please contact us, as some cases vary, or do not fit current conditions.

● THE TYPES OF HIDEX WHEELS

We are strongly convinced that using HIDEX WHEEL will help streamline your

grinding process, and by all means we recommend that you try it at least

once.

RETURN TO PRODUCTS

Responding to customers' demands, we have developed the HIDEX WHEEL. It uses polyimide resin as the main binding material which shows elasticity and excellent heat resistance. We might also add that compared to the conventional phenol resin wheels, It is an ultra long-life resin bond wheel that boasts of heat resistance and a high grasping power of abrasive grains. Shape retention of the HIDEX WHEEL is approximately three times (index 299) as long as our conventional resin bond wheel(index 100). We're offering four types of HIDEX WHEEL to match the cutting materials and condition of use.

Please contact us, as some cases vary, or do not fit current conditions.

● THE TYPES OF HIDEX WHEELS

| BB1 | :most priority is placed on grinding efficiency (oriented to sharpness) |

| BB2 | :highly improves the abrasive resistance of BB1 |

| BB3 | :improves the grinding efficiency of BB4, and has an intermediate performance between BB2 and BB4 |

| BB4 | :the highest priority is placed on abrasive resistance (oriented to long-life) |

RETURN TO PRODUCTS

バナースペース

Oriental Diamond Tool Lab.Ltd.

2-908-8 Shinmarukohigashi Kawasaki-shi Nakahara-ku Kanagawa-ken 211-0004 JAPAN

Phone +81-44-433-7171

FAX +81-44-411-0201